As the cannabis industry continues to pile up waste as a result of one-time use – everything from eighth jars to preroll tubes – the team at Sana Packaging is looking to chart a new course using plastic recycled from the ocean.

Like that nautical wordplay? Thank you. But in reality, we really are devastating the environment in recent years as an industry. And despite the heady ambiance traditionally associated with it, cannabis hasn’t helped. The carbon footprint around the production of cannabis is massive and two of the biggest factors are lighting and packaging. The fossil fuels needed for both would arguably be the biggest blight left on society as other problems with cannabis come to be treated as public health issues as opposed to criminal justice ones.

Lighting is a weird thing to focus on when chastising the cannabis industry’s carbon footprint. As we noted in our coverage of efforts to convert the California cannabis industry to energy-efficient LEDs for growing pot, it’s not a four-year-old legal industry’s fault we as a society haven’t taken more responsible approaches to producing power. The problem doesn’t start at the end when those HPS lights give plants a little extra kick.

But with packaging, there is certainly a lot more room to throw blame at the industry.

While under Prop. 215 we did see many jar recycling programs, they are few and far between in the supply chains of the legal era. Some might argue the burden of attempting to survive in cannabis since 2018 hurt R&D efforts in the packaging area. But regardless, the cannabis industry is generating tons of trash.

The team at Sana Packaging is doing their part to help alleviate some of the industry’s impact on the environment, while helping to clean it up. According to the company, it has already removed more than 45 tons of plastic waste from the ocean. That’s about seven and a half elephants. In addition to cleanup, Sana has used more than 54 tons of plant-based hemp plastic over the years creating their other products.

We talked with Sana Packaging’s cofounder and Chief Scientific Officer James Eichner to hear how the company went from being founded during grad school in 2016 to pulling all that trash out of the water.

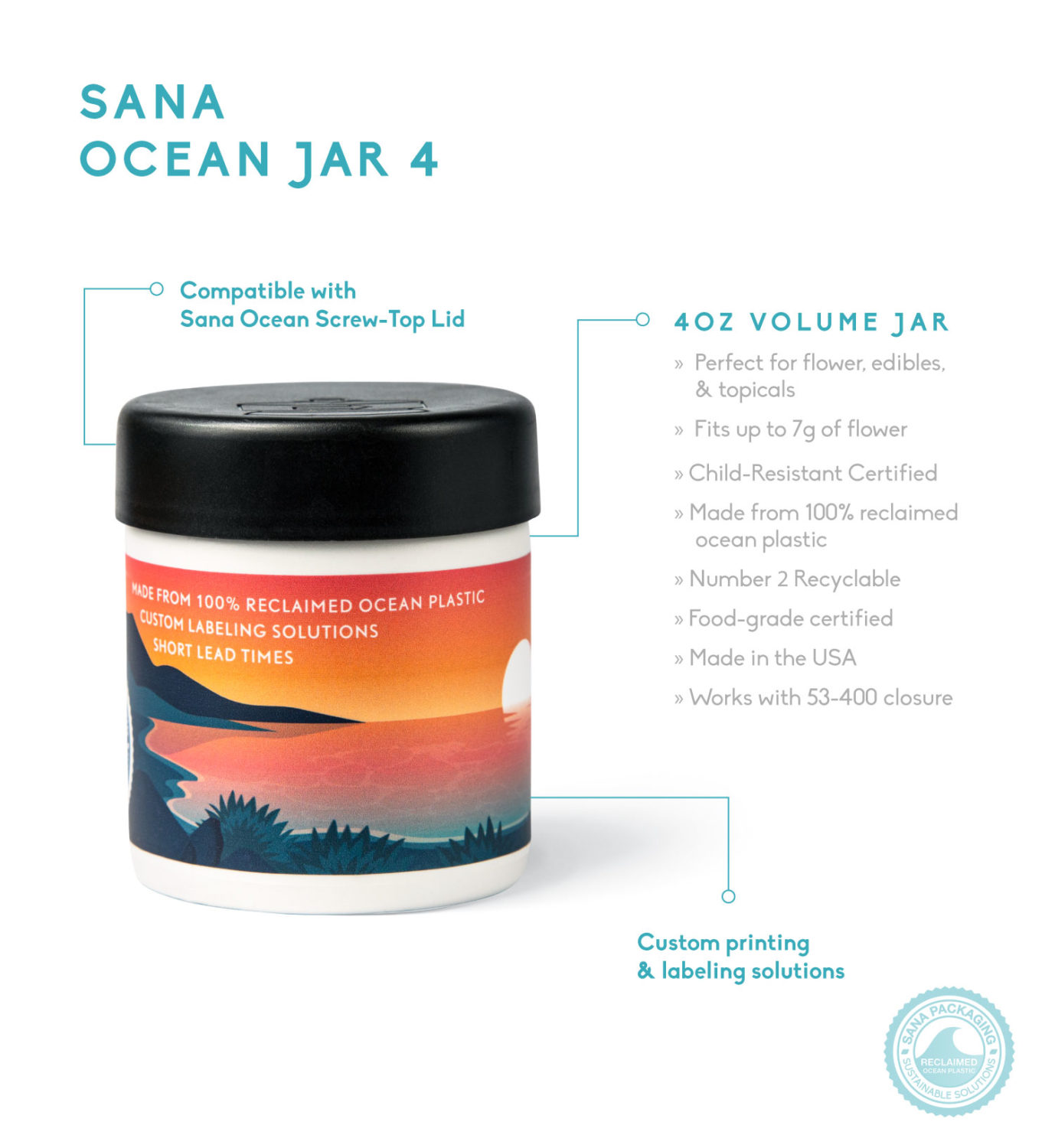

Eichner explained the first wave of recycled ocean material products were developed in the summer of 2018 and tested with some of the company’s big customers. “Now we’ve got five reclaimed ocean plastic products, the jar being the most recent one that we’ve released,” he told L.A. Weekly.

Eichner went on to note some reclaimed ocean plastics on the market are mixed materials, meaning the material sourced is a conglomerate of other reclaimed materials.

“That unfortunately doesn’t do anyone any good because a mixed material can’t go back into the proper waste stream,” Eichner explained. “So one of the big value ads that our supplier partner Oceanworks provides – they’re another L.A-based company – is the verification that we’re sourcing a pure material.”

Things in the proper waste stream don’t end up in a landfill.

“Plastic is a porous material, so it picks up contaminants. So as you can imagine, when you take it out of the ocean, it’s really dirty. So it needs to go through treatment. It’s got chemicals on it, it’s got a bunch of shit on it that obviously needs to be purged before it can be used,” Eichner said. “Not just in a manufacturing process, but also as packaging for a perishable product like cannabis.”

By the end of the cleanup, you get the FDA-certified quality of material Sana Packaging works with from Oceanworks. Sana is currently working with a reclaimed ocean high-density polyethylene.

Through the pandemic, sales were up over 132%. We asked Eichner what it’s been like getting the industry to be more receptive when talking about cleaning up its act. He said one of the things that helps is cannabis is willing to pay a bit more than other industries for the more ethical packaging as it becomes available.

“If you look at an industry like food and beverage, companies in that space are typically willing to pay about a 10 – 20% premium for a sustainable packaging material. But if you exceed that 10 or 20% premium, you’ll see your customers drop off like flies. That’s just a much more sensitive industry. For a variety of reasons, cannabis has a much higher willingness to pay,” Eichner said. “Our first products were at a 300% premium compared to your cheapest alternatives.”

Eichner argues one factor is cannabis feels like a more personalized thing than much of the food and beverage space. Seeing the packaging, it feels a lot different in a grocery store than a dispensary. He also believes it’s such a rapidly growing industry that has so many different needs and pain points associated with packaging that there’s actually room for a company like Sana to exist in the first place. “I think it would be much more difficult to launch a sustainable and circular packaging startup if you are tackling one of these more price-sensitive industries,” said Eichner.

Eichner said another piece of the intrigue early on was helping cannabis move to more sustainable packing from the outset of the industry as opposed to cleaning it up. We asked if we were already past the point of no return on those hopes since so much waste is being generated?

“A lot has happened in the last few years. And I definitely think cannabis packaging got off to a really bad start. But I don’t think we’re too far gone,” he replied.

Advertising disclosure: We may receive compensation for some of the links in our stories. Thank you for supporting LA Weekly and our advertisers.